All Categories

All Categories

Small Spring Packing Machine

- Country of origin: Shanghai,China

- Brand: Huihe

- HS code:

- Yield:

- Type of shipping: ocean shipping

- Port of shipment: Shanghai

- Supply capacity: 500 Set/Sets per Month

- Packing method: Packed into one standard export wooden case

DXDK240 Small Spring Packing Machine

Description

1.Can finish the function of bag making, measuring,filling,sealing,cutting and counting.

2.Controlled by computer and step motor pull bag, flexible bag length cutting, operator

needn't to adjust the unloading working, saving time and saving films.

3.Separate PID control to temperature, suitable for various packing materials.

4. Option device: ribbon printer, filling device, gasexhaust device, horizontal sealing

punching device, rotary cutter, small cutter, former beat device, batch pneumatic cutter.

5.Simple driven system, working more stable and easy to maintain.

6. Packing material:(PET/PE), (Paper/PE), (PET/AL/PE), (OPP/PE)

Features

LCD screen, intelligent control, failure warning, Solid intelligence double road temperature

control, The design of circulatory wind-electric cabinet for 24 hours working, 304 stainless steel

Specification

|

Model No. |

DXDK-240 |

|

Packing speed |

40-60bag/min |

|

Range of measurement |

5-100ml 0-5ml (fixed cup on single tray) |

|

Bag size |

W: 30-120mm L:30-170mm |

|

Voltage |

380V or 220V or made accordingly |

|

Power |

1400W |

|

Dimension |

625×751×1558mm |

|

Packing material |

(PET/PE), (Paper/PE), (PET/AL/PE), (OPP/PE) |

|

Method of Measurement |

Cup type |

|

Weight |

200kg |

Main electric parts brand:

Inverter: Tan'an Taiwan brand, main motor: SHANMA, Shanghai brand, reducer: Gongji, Taiwan brand, fan: Best, Germany brand, Temperature controller: Yatai, Shanghai brand, proximity sensor: Riko, Taiwan brand

Our packing sample

After Sales Service:

1.Guaranty: One Year.

2.One set of consumable accessories will be provided with the machine.

3.Any question, you can mail/call us at any time. And our most experienced engineers are assigned to give consulting service, and always available for dispatching abroad.

4.All spare parts are always available for delivery.

5.Manual is in English.

Installation/ Training

If really dont know how to install and operate after showing the video and telephone instruction, you can ask for installation from us. It must be after shipment till the machine has arrived and factory must be ready equipped with all necessary requirements before booking installation. Our engineers will come to the site for the complete and final installation. During the installation session, a one-day training course will be provided to our customers about operation and maintenance procedure. The following costs should be paid by the buyer, including engineer's all local transportation, accommodation, and air tickets (round trip).

Payment terms

Choose the machine type → Goods delivery :(FOB,CIF,CFR,EXW) → Payment term :30% down payment as for ordering the machine (or 100 % payment that can save time ) → Confirmed the machine requirement → Based on your requested to producing machine→ Though video chat or send machine picture or directly come to inspection in our factory → Pay the rest of balance 70% → Arrange the shipment .(If need more technical support ,please contact our services )

Our machines are working in our customers' factory

Our Customers

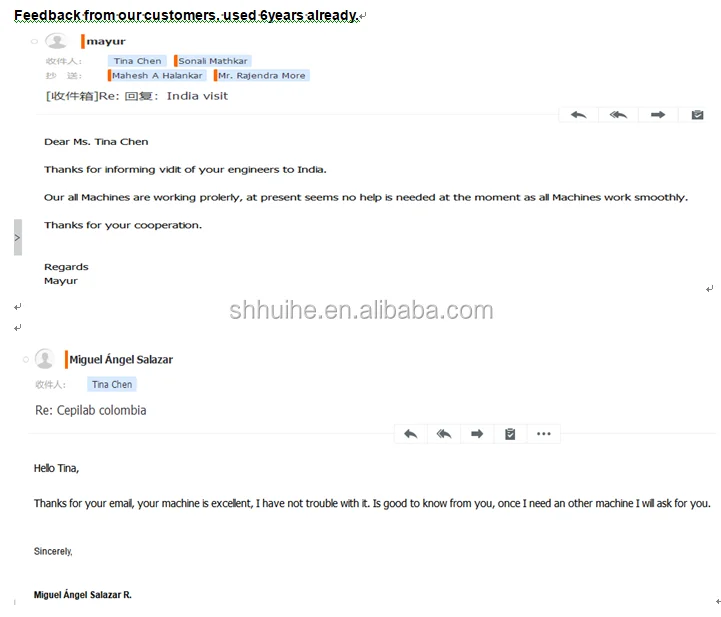

Our Customers' feedback

Our Certificate

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )  ( 0 )

( 0 )

No information

English

English

Chinese

Chinese

Select Language

Select Language