All Categories

All Categories - Machinery

Industrial Supplys Refrigeration & Heat Exchange Equipment Industrial Filtration Equipment Energy Saving Equipment Ventilation Fan Parts Industrial Brake Boilers Gas Generation Equipment Parts Industrial Air Conditioners Oil Purifier Air Cleaning Equipment Parts Air-Compressor Parts Gas Generation Equipment Boiler Parts Energy Saving Equipment Parts Refrigeration & Heat Exchange Parts Air Conditioner Parts Air-Compressors Cleaning Equipment Parts Motor Parts Ventilation Fans Filter Supplies Laser Equipment Evaporator Engine Parts Motors Cleaning Equipment Engines Air Cleaning Equipment Laser Equipment PartsMetal Processing Machinery Metal Processing Machinery Parts Machine Tools Accessory Metal Processing Machinery Machine ToolsOther Machinery Home Product Machinery Pharmaceutical & Chemical Product Machinery Chemical Process Machinery Mining & Metallurgy Machinery Wood Working Machinery Raw Material Processing Machinery Other MachineryPackaging Machinery Packaging Line Laminating Machine Packaging Machinery Parts Capping Machine Blister Packaging Machine Auxiliary Packaging Equipment Gluing Machine Filling Machine Multi-Function Packaging Machine Sealing Machine Packaging Forming Machine Wrapping Machine Vacuum Packing Machine Coating Machine Labeling Machine Packaging Machinery Packaging MachineryConstruction Machinery Building Material Making Machinery Parts Building Material Making Machinery Construction Machinery Construction Machinery PartsFood & Beverage Processing Machinery Food Processing Machinery Parts Beverage Processing Machinery Parts Beverage Processing Machinery Food Processing MachineryPrinting Machinery Offset Printer Pad Printer Rotogravure Printing Machine Post-Press Equipment Heat Transfer Laser Printer Flexographic Printer Digital Printer Inkjet Printer Pre-Press Equipment Printing Machinery Printing Machinery PartsApparel & Textile Machinery Cap Making Machinery Parts Bag Making Machinery Parts Cap Making Machinery Leather Production Machinery Parts Belt Making Machinery Parts Apparel Machinery Parts Bag Making Machinery Leather Production Machinery Sock Knitting Machinery Belt Making Machinery Home Textile Product Machinery Parts Sock Knitting Machinery Parts Glove Making Machinery Textile Machinery Textile Machinery Parts Home Textile Product Machinery Apparel Machinery Shoemaking MachineryAgricultural Machinery Forestry Machinery Farm Machinery Parts Animal Husbandry Equipment Farm Machinery Biomass Dryer Hydroseeding Machine Fishery Machinery Planting & Fertilizing Machine Forestry Machine Other Agricultural Machinery Slaughtering Equipment Agricultural Mower Oil Presser Livestock Machinery Harvesting Machine Agricultural Machinery Parts Feed Processing Machinery Agricultural Sprayers TillerMachine Tools Pharmaceutical equipment and machinery Honing Machine Other Machine Tools Gear Cutting Machine Special Machine Tools Grinding Machine Saw Bench Punching Machine Lathe Milling Machine Drilling Machine CNC Machine Tools Machine Tools AccessoriesMould Extrusion Die Other Moulds Compression Mould Metal Casting Mould Drawing Die Rubber Mould Blowing Mould Forging Mould Die-Casting Mould Preform Mould Mould Parts Stamping Die Plastic MouldPower & Generating Sets Steam Turbine Generator Generator Parts & Accessories Other Generators Solar Generator Hydro Generator Wind Generator Gasoline Generator Gas Generator Diesel GeneratorCasting & Forging Vacuum Casting Gravity Casting Sand Casting Metal Casting Lost Wax Casting Die Casting

- Vehicles & Accessories

Auto Parts Universal Parts Auto Engine Steering System Other Auto Parts Body Parts Auto Electrical System Auto Drivetrain Slewing Drive Auto Bearing Brake Auto Filter Suspension System Shock Absorber Wheel Hub, Rim & SpokeVehicle Repair Equipment & Tools Vehicle Tools Vehicle Equipment Booster Cables Wheel Balancer Warning Triangle Jump Starter Other Auto Repair Equipment & Tools Car Bench Tire Inflator Automotive Test Equipment Tyre Changer Diagnostic Tool Auto Painting Equipment Wheel Alignment Repair Tools Car LiftMotorcycle Parts & Accessories Motorcycle Tail Boxes Motorcycle Ramps Motorcycle Cover Motorcycle Steering Motorcycle Wheels Motorcycle Brakes Motorcycle Engines Motorcycle Electrical System Motorcycle Transmissions Motorcycle Body Parts Motorcycle Stickers Automotive & Motorcycle Parts Agent Motorcycle Bags Motorcycle Tires Motorcycle Helmets Other Motorcycle Accessories Other Motorcycle Parts Motorcycle Electronics Motorcycle Luggage Motorcycle Helmets Motorcycle Shock Absorber Other Motorcycle Parts & Accessories Motorcycle Steering & Transmission System Motorcycle Body Parts Motorcycle Engine Motorcycle Battery Motorcycles & Scooters & bicyclesCar Maintenance Car Care Equipment Car Care Products Car Cleaning Tools Car Polisher Car Cleaning Chemical High Pressure Car Washer Other Car MaintenanceCar Accessories Exterior Accessories Shift Knob Car Ramp Car Fender Side Step Spoiler Car Grille Car Glass & Window Other Car Accessories Car Door Tail Lift Car Seat Car Bumper Wiper Blade, Arm & MotorCar Decoration Interior Accessories License Plate Frame Car Holder Car Perfume & Air Freshener Car Roof Box & Rack Car Seat Cover & Cushion Car Sunshade Other Car Decoration Window Visor Car Mat Car Organizer Steering Wheel Covers Car Cover Car StickerElectric Vehicle & Parts Electric Motorcycle ATV Parts ATV Tricycles Handicap Scooter Electric Car Parts of Electric Bike Electric BikeCar Light & Auto Mirror Rear View Mirror Fog Light Other Car Lights & Auto Mirrors LED Light Bar HeadlightAuto Engine Structure Other Auto Engine Structure Exhaust System Cooling System Valve System Fuel System

- Electrical & Telecoms

Optical Fiber, Cable & Wire Control Cables Instrumentation Cables Power Cords & Extension Cords Audio & Video Cables Electrical Wires Wiring Harness Other Wires, Cables & Cable Assemblies Power Cables Cable Manufacturing Equipment Power Cord & Extension CordPower Supply & Distribution Laptop Adapter Inductors AC/DC Adapters Voltage Regulators/Stabilizers Industrial Power Supply Other Power Supplies Inverters & Converters Switching Power Supply Uninterrupted Power Supply (UPS)Batteries Solar Cells, Solar Panel Button Cell Batteries Storage Batteries Other Batteries Electrical Ceramics Primary & Dry Batteries Battery Packs Fuel Cells Rechargeable BatteriesPower Tools Heat Gun Electric Wrench Electric Pipe Threader Electric Planer Electric Screwdriver Hot Melt Glue Sticks Glue Gun Electric Saw Sanding Disc Electric Drill Other Power Tools Polisher Electric Trimmer Polishing Pad Electric Hammer Grinding Wheel Pneumatic Tools Spray Gun Blower Drill Bit Grinder Hydraulic Tools Nail Gun Sander Saw BladeSwitches Toggle Switches DIP Switches Time Switches Rocker Switches Flow Switches Pressure Switches Limit Switches Remote Control Switches Other Switches Push Button Switches Rotary Switches Slide Switches Wall SwitchesGenerators Gasoline Generators Other Generators Generator Parts & Accessories Alternative Energy Generators Gas Turbine Generators Diesel Generators

- Lights & Lighting

Lighting Fixtures Other Lighting Fixtures Emergency Lights Holiday Lighting Portable Lighting Industrial Lighting Professional Lighting Residential Lighting Outdoor Lighting LED Lighting

- Packaging & Printing

Packaging Types Media Packaging Apparel Packaging Protective Packaging Chemical Packaging Other Packaging Applications Electronics Packaging Paper Packaging Food Packaging Plastic Packaging Cosmetics Packaging Tobacco Packaging Pharmaceutical Packaging Agricultural Packaging Gift Packaging Transport PackagingPackaging Products Handles Cans Packaging Tubes Packaging Trays Packaging Rope Bottles Jars Blister Cards Adhesive Tape Lids, Bottle Caps, Closures Packaging Bags Packaging Labels Packaging Boxes StrappingPackaging & Printing Materials Pulp Shrink Film Metallized Film Printing Inks Hot Stamping Foil Stretch Film Printing Plate Printing Mesh Transfer Film Other Printing Materials Transfer Paper Paper & Paperboard Composite Packaging Materials Aluminum Foil Other Packaging Materials

- Hardware

Finished Hardware Furniture Hardware Hardware Supplies General Hardware Mechanical Hardware Construction HardwareMachinery & Parts Plastic Product Making Machinery Parts Rubber Product Making Machinery Parts Rubber Processing Machinery Parts Plastic Processing Machinery Parts

- Chemicals & Energy

Plastic Products Plastic Cards Agricultural Plastic Products Automotive Plastic Products Medical Plastic Plastic Tubes Plastic Rods Home Appliance Plastic Electronic Plastic Plastic Sheets Other Plastic Products Plastic Nets Composite Pipes

- Home & Gardening & Construction

Home & Garden Home storage & organization Rain gear Baby products and supplies Drinkware Cooking tools Coffee utensils Home Decoration Kitchenware Bathroom Products tableware

- Packaging & Office

- Health & Beauty

- Gifts, Sports & Toys

- Electronics

- Bags, Shoes & Accessories

- Apparel & Textiles

- Security & Protection

- More

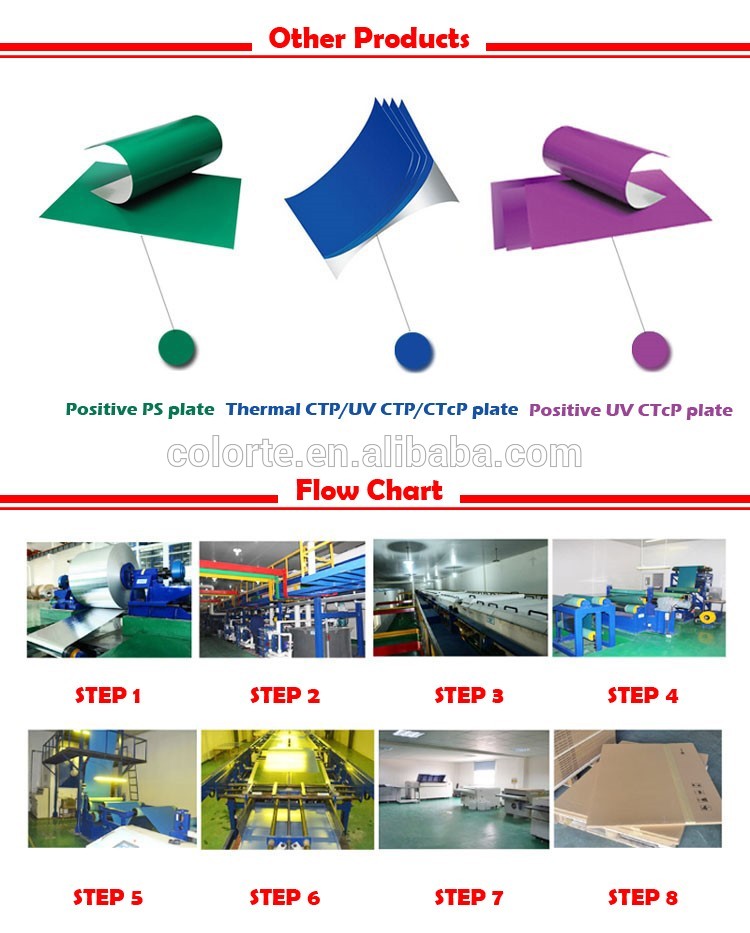

High Quality New Offset Printing use Positive CTP Plate/UV Ctp Plate,polymer plate

Huaguang brand UV-PII New CTcP Plate

Based on Huaguang UV-P plate, UV-PII is a new generation of CTcP plate to meet the market requirements for speed and efficiency. The new photosensitive layer and stable production process not only increase its sensitivity (25% higher) but also maintain the excellent performance of plate making and printing same to UV-P. UV-PII, with good developing and plate-making compatibility, is the best choice for offset packaging and commercial printing.

Technical Specification

Plate Type: UV-PII-type UV-CTP plate, also used as high sensitivity PS plate.

Application: Commercial sheetfed and rotary press printing

Substrate: Electrochemically grained and anodized aluminum

Gauge: 0.15/0.20/0.25/0.30/0.40 mm

Final image color: Blue-Green

Spectral sensitivity: 350-460nm UV light, especially 400-410nm UV laser

Relative Sensitivity: 40±5 mW(Cron UV-4632CI platesetter Parameter 1000 rpm)

Resolution: 2-98% @ 250 lpi.( The difference between plate-making equipment will be different)

Applicable: main UV-CTP platesetters such as Cron, luscher, Amsky, basysPrint.

platesetter: (unbaked)18 months, run length will be different when used in different conditions such as printing presses/paper/ink/printing chemicals and etc,.

Run length: Yellow light

Safelights: 18 months under recommended storage conditions

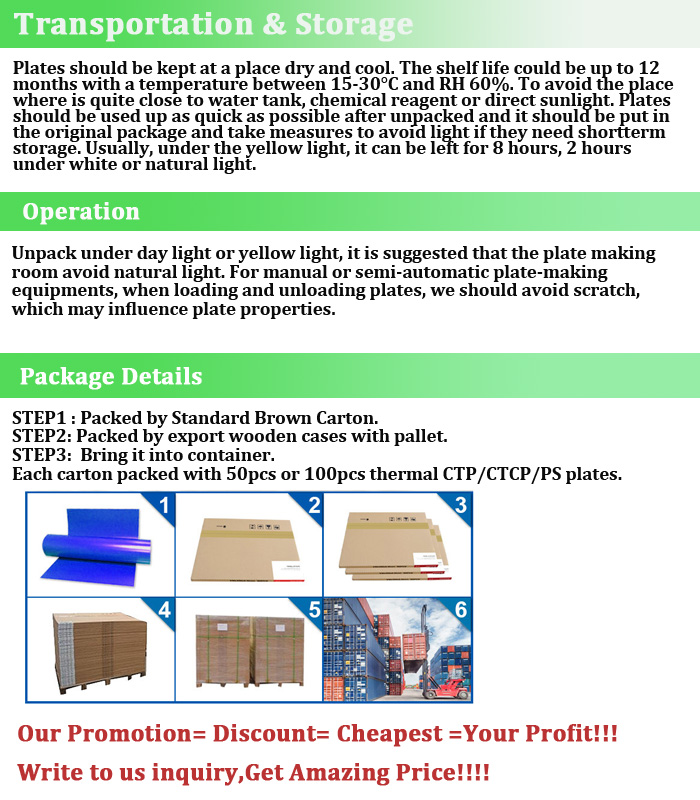

Processing Conditions: The processing of UV-PII may follow UV-P processing conditions. Huaguang positive PS plate developer (PD) is recommended. Recommended conditions:

Developer: Huaguang PD positive PS plate developer

The ratio of developing solution (PD: water): 1:3-1:4

Developing temperature: 24±1°C

Developing time: 20-30s

Washing temperature: Room temperature

Drying temperature: 50°C

Replenishing Rate: 100—150 ml/m2

| Company type | Main products | ||

|---|---|---|---|

| Company website | Employees | ||

| Corporation legal person | Member Since | ||

| Registered capital | Company address |

| Major markets | Export ratio | ||

|---|---|---|---|

| Annual sales | Annual purchase amount | ||

| Export mode | Registration Form No. of foreign trade operators: English name of the company in the registration form: | Photos of registration form | |

| Nearby port | Date of delivery | ||

| Barter terms | Payment method |

| Factory area | Number of production lines | ||

|---|---|---|---|

| Factory address | Provide OEM service | no | |

| Company management system certificate | Product certificate |

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )  ( 0 )

( 0 )

No information

English

English

Chinese

Chinese

Select Language

Select Language