All Categories

All Categories

Vegetable Vacuum Cooler from 300kg~5000kg

Specifications:

Condition:New

Place of Origin:Guangdong, China (Mainland)

Brand Name:ICEUPS

Model Number:KMS-02P

Type:Dehydrator

Voltage:380v/50hz/3p or others

Power(W):47.4kw

Weight:7800kg

Dimension(L*W*H):5360X2600X2200mm

Certification:CE/ISO9001

Warranty:15months after B/L date

After-sales Service Provided:Engineers available to service machinery overseas

Processing capacity(2 Pallet):1000kg/time

Application:quickest cooling for vegetables,fruits,flowers

processing time:20~30minutes

Chamber Material:stainless steel or painted

temperature after processing:up to 1°C

Vacuum Pump brands:Busch or Leybold

cooling mode:air cooling,water cooling or evaporative cooling

Door type of vacuum chamber:Upward lifting,Horizontal sliding and Manual operating

Refrigerant:R22 or R404a

Control system:full automatic PLC control system

Product Description:

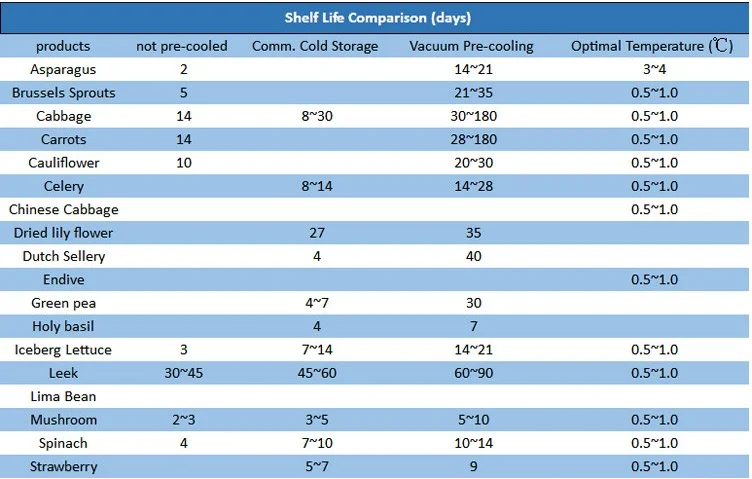

1.Vacuum Cooler is the quickest and most cost-effective cooling system for vegetable, fruits, flowers & more.

2.Vacuum cooler, which can strongly improve your product quality and at the same time reduce your cooling costs, is now becoming an acceptable investment for almost all vegetable growers!

3.Vacuum Cooler cools fresh product quickly and uniformly in large loads within 15-30mins/cycle, also suitable for packed produces.

ICEUPS will design and offer the most suitable machine according to clients'requirements.

* Vacuum Cooler Machine Condenser System Type:

1) Air condenser:The simplest construction, suitable for small system.Easy to integrate.

2) Water condenser: Low cost, efficient and easy to install. Perfect for most districts climates.

3)Evaporative condenser: Optional system for dry climates, or if water availability is limited.

*Door type of Vacuum Cooler Machine

1) Standard swing door: The simplest construction, manual operation. The ramp for this system is relatively long, and is mounted inside the cooling chamber.

2)Horizontal sliding door: This eletrical driven door is optimal if the cooling skid is placed ,besides the vaccum chamber (one pallet modle and more than 6 pallets systems).

3)Upward lift door:Suggested solution for all systems from 2-6 pallets. Easy installation , easy ramp construction.

Please contact ME to get more technical information & quotations.

SPECIFICATIONS FOR 3000KG VACUUM COOLER | |||

Vacuum cooler | Model | KMS-02P | 1000kg/2 pallets |

processing temperature | From 30°C to 2°C | 20-30 Minutes | |

Vacuum chamer Dimensions | 2600x2600x2200 | mm | |

Main performance parameters | Refrigeration capacity | 88.5 | kw |

Compressor power | 28.7 | kw | |

Evaporating temperature | 15 | u2103 | |

Operation system | power supply | 380v/50hz/3p | or 220v,415v,480v |

Refrigerant | R404a | or R22 | |

Automatic control system | PLC | schneider/LS | |

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )  ( 0 )

( 0 )

No information

English

English

Chinese

Chinese

Select Language

Select Language