All Categories

All Categories

Tunnel oven Full automatic Soft & Hard Biscuit Production Line/Biscuit processing equipment industrial machinery

- Country of origin:

- Brand:

- HS code:

- Yield:

- Type of shipping:

- Port of shipment:

- Supply capacity:

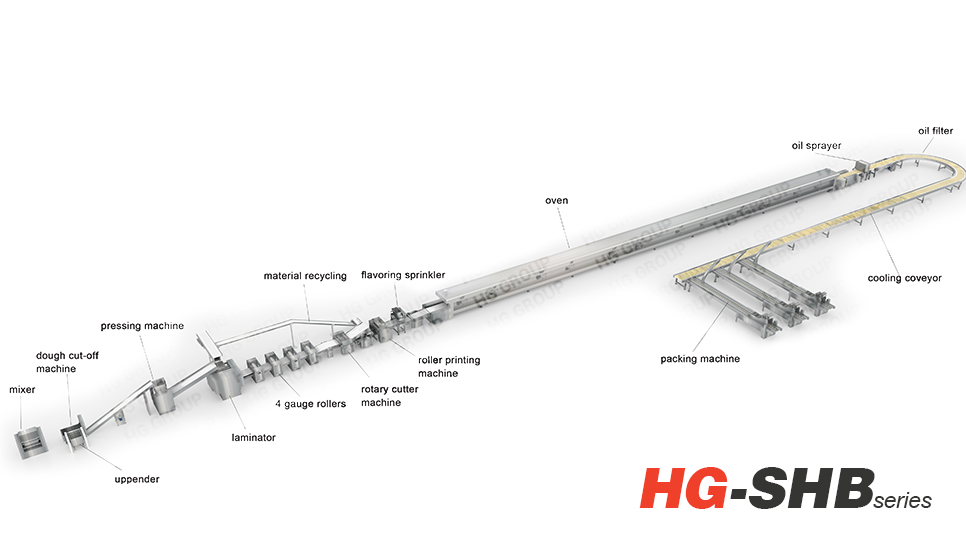

- Packing method:

HG- SWB Full automatic Soft/Hard Biscuit Production Line can produce soft biscuit, hard biscuit, soda biscuit. By using different forming mold, it can produce different size & shape biscuit.It also can produce sandwich biscuit by adding sandwich device.

Capacity and Details

HG Industry Group can provide turn key project solution of Biscuit Making Machine. We have five standard capacity model options: HG-SWB280--100kg/h; HG-SWB480--200kg/h; HG-SWB620--500kg/h; HG-SWB1000---1000kg/h; HG-SWB1200--1200kg/h. Besides we can provide customized biscuit machine solution according to client’s specific requirements.

Advantages:

1)PLC controlling system, easy to operate

2)Distribute baking zone design to ensure biscuit quality

3)304stainless steel raw materials with high configuration and stable performance

4)Advanced depositor that can control cake weight precisely

5)Wide application for various shape biscuit

6)Automatic biscuit production line solution with less labor & life time maintenance service

hg Production Line

Full-automatic Soft | Hard | Soda | Bear BiscuitsProduce food

Apply to :::Biscuit Production Line

Full-automatic Soft / Hard / Soda / Bear Biscuit Production Line is a new generation of advanced equipment that can produce biscuits such as hard biscuits, soft biscuits, soda biscuits, sandwich biscuits, etc. Oven and machine shells are all made of stainless steel. This line has the character of big production capacity, Stable running, good-looking surface, easy operation, etc.

3385

Full automatic Soft & Hard Biscuit Production Line is a new generation advanced equipment which can produce biscuits such as hard biscuit.

Soft / Hard Biscuit Machine

Bear Biscuits / Hard Biscuits / Soda<br>Biscuits / Soft Biscuits

Biscuits Series

Soft & Hard Biscuit Production Line

Production Line

kWlDPFUbq2I

/hg-machine/2020/07/15/hg-shb-3.png

/hg-machine/2020/07/15/hg-shb-4.jpg

/hg-machine/2020/07/15/hg-shb-5.jpg

/hg-machine/2020/07/15/hg-shb-6.jpg

/hg-machine/2020/07/15/hg-shb-7.jpg

/hg-machine/2020/07/15/hg-shb-8.jpg

/hg-machine/2020/07/15/hg-shb-9.png

/hg-machine/2020/07/15/hg-shb-10.png

/hg-machine/2020/07/15/hg-shb-11.png

Bear Biscuits / Hard Biscuits / Soda Biscuits / Soft Biscuits

Process

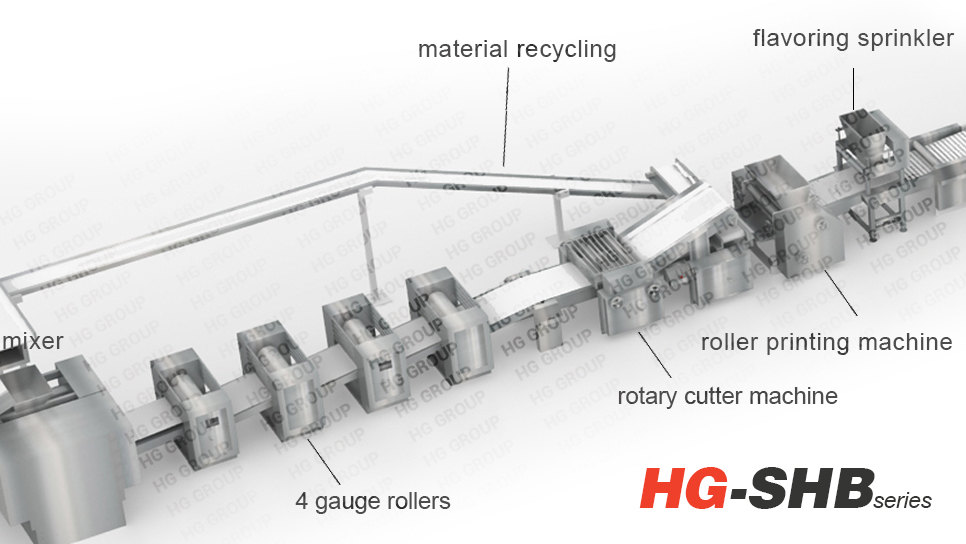

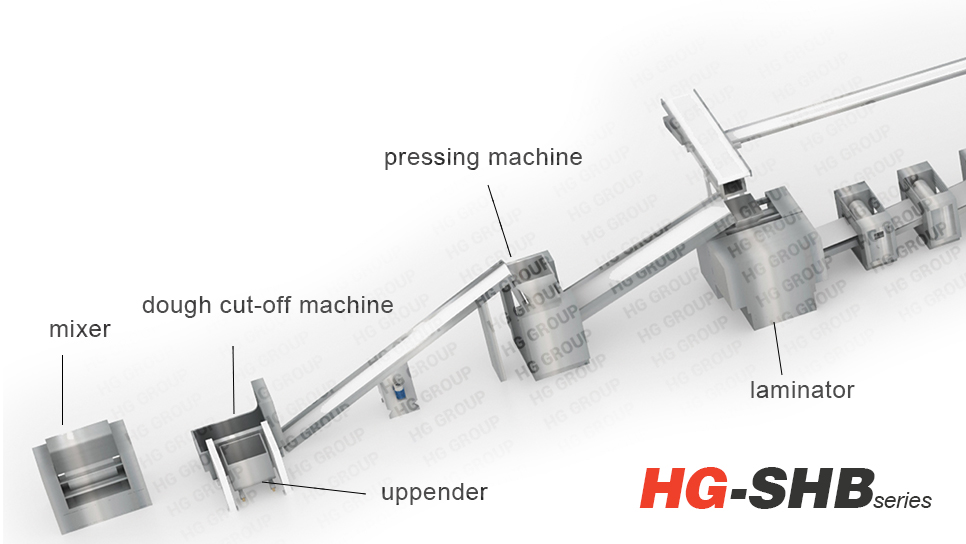

- 1.dough mixer

- 2.cutting and lifting

- 3.first pressing

- 4.dough flatting

- 5.forming

- 6.sugar sprinkle

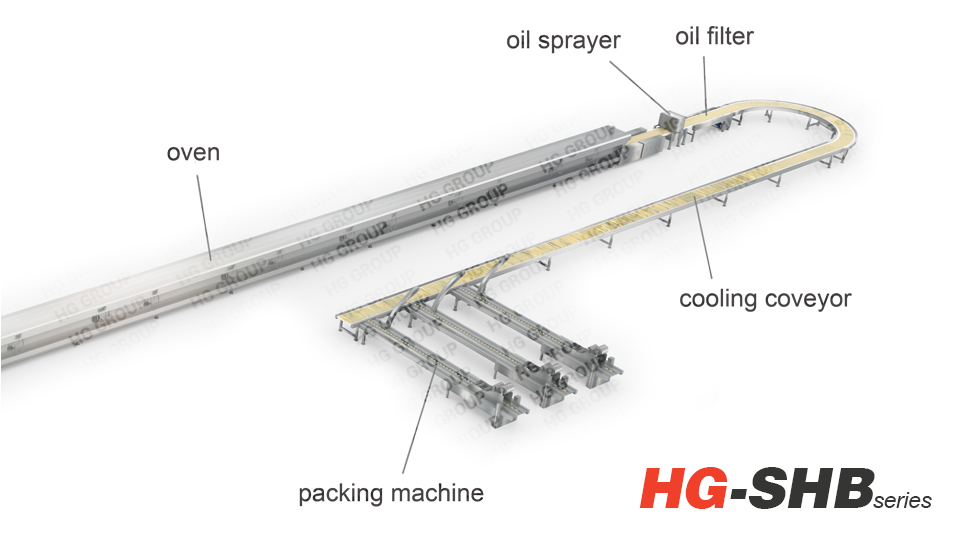

- 7.baking

- 8.drench oil

- 9.oil filter

- 10.turn over

- 11.cooling conveyor

- 12.stacking

- 13.packing

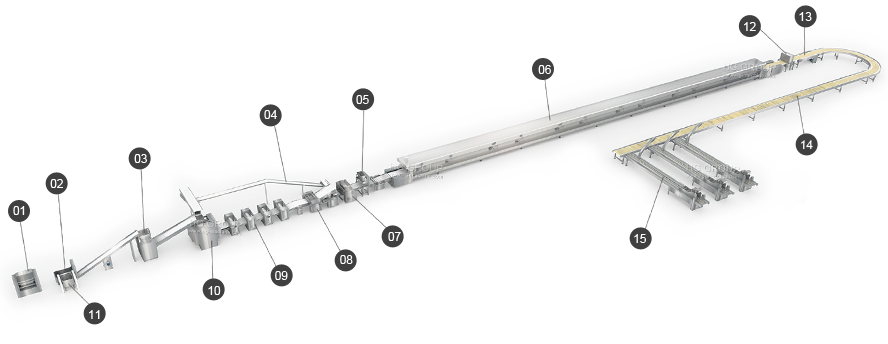

- 01mixer

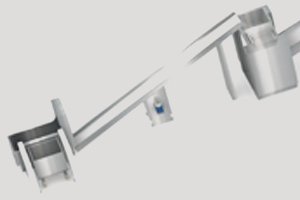

- 02dough cut-off

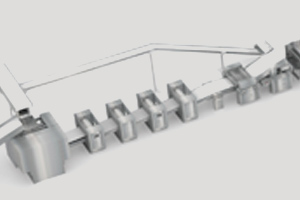

machine - 03pressing machine

- 04material recycling

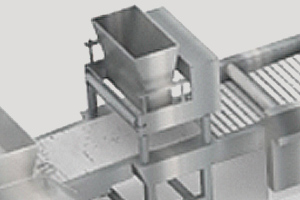

- 05flavoring sprinkler

- 06oven

- 07roller printing

machine - 08rotary cutter

machine - 094 gauge rollers

- 10laminator

- 11uppender

- 12oil sprayer

- 13oil filter

- 14cooling coveyor

- 15packing machine

Production Process

dough mixer

cutting and lifting

pressing and forming

flavoring

baking

conveyor and packing

Knowledge of Full automatic Soft/Hard Biscuit Production Line

Daily cleaning of Biscuit Making Machine

- With factory price Full automatic Baked Potato Chips Production Line/Baking potato chips machine other snack machines

- Full-automatic Bear Cake Production Line/Doughnut cake bakery equipment machine for small business bakery equipment

- Full automatic Multifunctional Wafer stick Machine/Wafer roll making production line other machinery & industrial equipment

- Full-automatic Compound Potato Chips Production Line/Pringles type potato chips machine other machinery & industrial equipment

- Natural Potato Chips Production Line/potato peeling machine manufacturing machines for small business ideas other snack machines

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )  ( 0 )

( 0 )

No information

English

English

Chinese

Chinese

Select Language

Select Language