All Categories

All Categories

Full-automatic Compound Potato Chips Production Line/Pringles type potato chips machine other machinery & industrial equipment

- Country of origin:

- Brand:

- HS code:

- Yield:

- Type of shipping:

- Port of shipment:

- Supply capacity:

- Packing method:

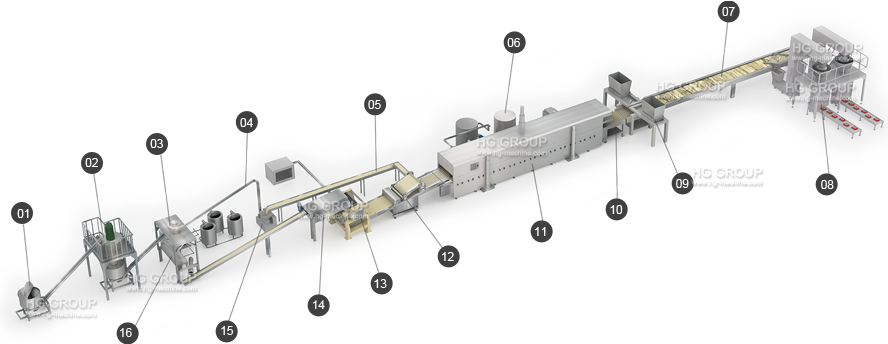

HG-CPC Full automatic Compound potato chips production line can make potato chips similar like Pringles, it is a very famous snack food popular with people of all ages. When we talk about the types of potato chips, there are huge differences between them. First type is the compound potato chips such as pringles we mentioned above. It is made by potato powder and potato starch and other power typed raw material mixed together, then through process of sheeting and forming and frying, we can get final potato chips with crispy taste. The second type is fresh potato chips, just as its name implies “fresh “ means fresh potatoes like Lays. Its raw material is just fresh potato by processing of washing, peeling, blanching , cutting and frying. By replacing the cutter we can different shapes of fresh potato chips. The last type is Baked potato chips production line, its raw material are same with compound type, the difference is the oven .Baked chips products dont need to fry , it is baked by tunnel oven similar like biscuit oven. Baked chips are more and more popular at present, because of the idea of healthy diet spreading in our daily life.

Capacity and Utilities:

HG Food Machinery manufacturer can provide machinery capacity 250kg/h and 500kg/h

Workshop requirements length 50m and width 10m

Power : 130-150kw

Gas consumption : 30kg/h-50kg/h

Compressed air consumption :0.8-1.0 m3/h

Advantages :

1)Complete potato chips production line with smart PLC controlling system.

2)Less worker operation.

3)With oil filtering system, which can improve oil quality in the fryer

4)Double roller sheeting machine and can adjust the thickness of chips between 0.8-1mm

5)Continous dosing system can realize a proper water and powder proportion automatically

Food standard raw material stainless steel and advanced configuration

hg Production Line

Full-automatic Compound Potato ChipsProduce food

Apply to :::Potato Chips Production Line

The potato chips equipment uses 304 stainless steel material and electronic parts are imported, thus the line can have long and stable running. this machine with high automation and the price is much cheaper than the European machine. but the quality is near to the European level. The flavor of the potato chips can be different. so the market for the potato chips is huge and can get a high profit!

3410

Full automatic Compound potato chips production line which absorbing European and American technology and our company take many years to develop and research this line independently.

Compound Potato Chips Machine

Compound Potato Chips / Oil-fried Potato Chips

Compound Potato Chips

Compound Potato Chips Production Line

Production Line

ft9Z7DovIMc

/hg-machine/2020/07/15/hg-cpc-3.png

/hg-machine/2020/07/15/hg-cpc-4.jpg

/hg-machine/2020/07/15/hg-cpc-5.jpg

/hg-machine/2020/07/15/hg-cpc-6.jpg

/hg-machine/2020/07/15/hg-cpc-7.jpg

/hg-machine/2020/07/15/hg-cpc-8.jpg

/hg-machine/2020/07/15/hg-cpc-9.png

/hg-machine/2020/07/15/hg-cpc-10.png

/hg-machine/2020/07/15/hg-cpc-11.png

Compound Potato Chips / Oil-fried Potato Chips

Process

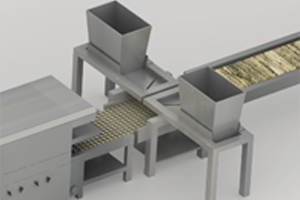

- 1.Mixing

- 2.Lifting

- 3.Dosing

- 4.Mixer

- 5.Lifing and spread out

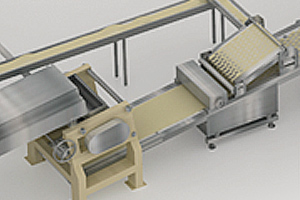

- 6.Sheeting

- 7.Forming

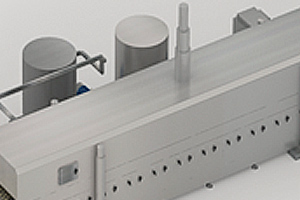

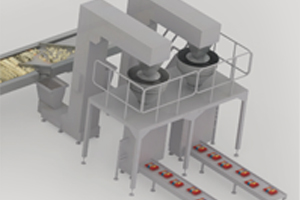

- 8.Oil frying

- 9.Oil filtering

- 10.Spraying the season

- 11.Cooling and Collecting

- 12.Packing

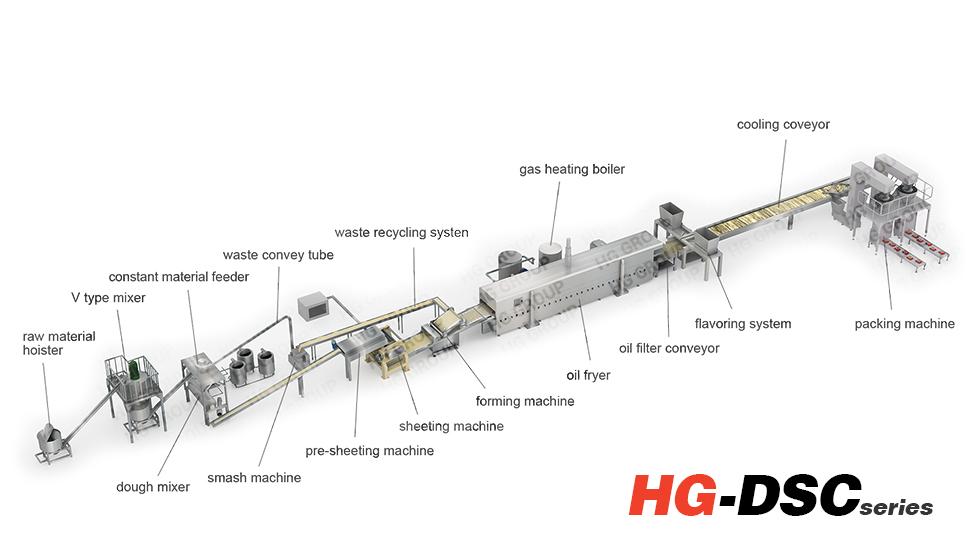

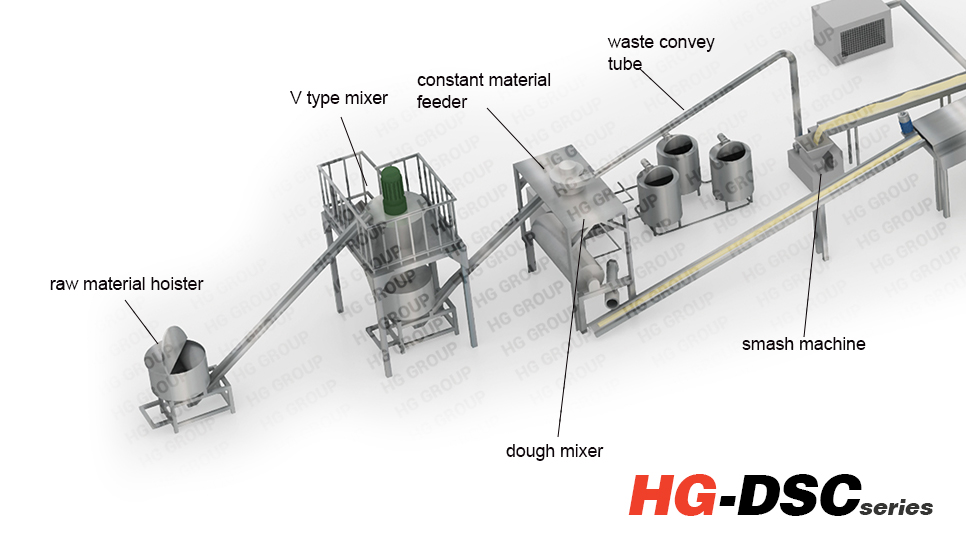

- 01raw material

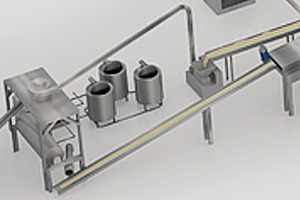

hoister - 02V type mixer

- 03constant material

feeder - 04waste convey

tube - 05waste recycling

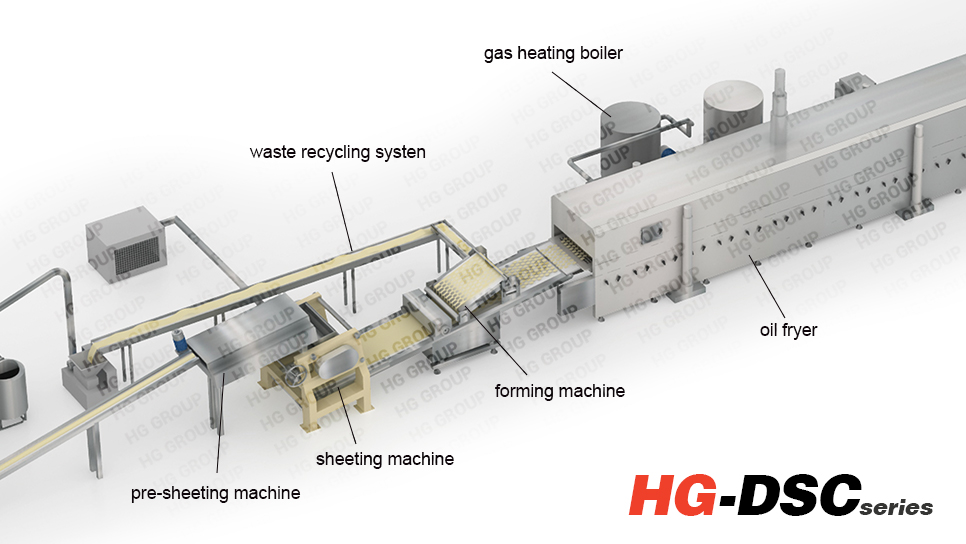

systen - 06gas heating

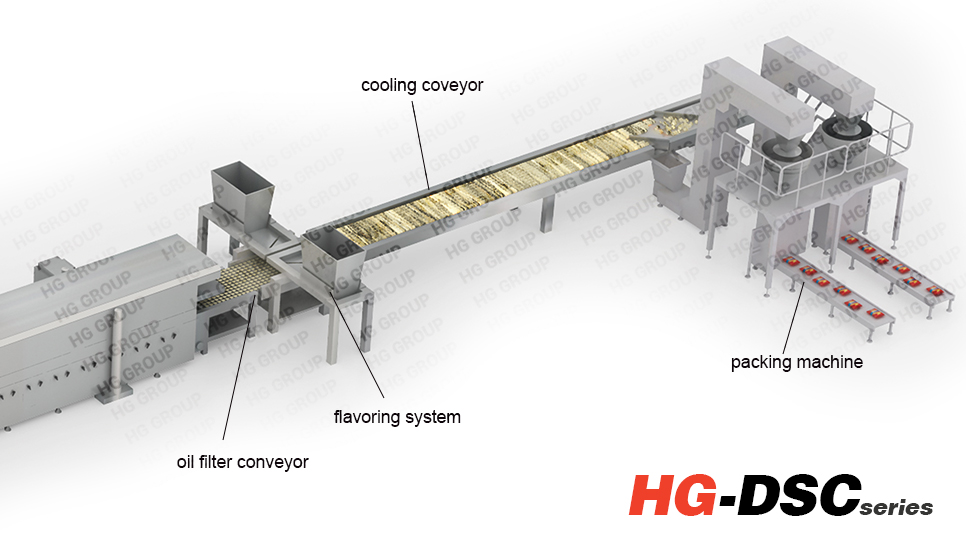

boiler - 07cooling coveyor

- 08packing machine

- 09flavoring system

- 10oil filter

conveyor - 11oil fryer

- 12forming machine

- 13sheeting machine

- 14pre-sheeting

machine - 15smash machine

- 16dough mixer

Production Process

-

mixing & dosing

mixer & lifing and spread out

sheeting & forming

oil frying

oil filtering & spraying the season

cooling and Collecting & packing

Functions of Full-automatic Potato Chips Machine

Features of Full-automatic Compound Potato Chips Production Line

Knowledge of Potato Chips Line

- With factory price Full automatic Baked Potato Chips Production Line/Baking potato chips machine other snack machines

- Full-automatic Bear Cake Production Line/Doughnut cake bakery equipment machine for small business bakery equipment

- Full automatic Multifunctional Wafer stick Machine/Wafer roll making production line other machinery & industrial equipment

- Full-automatic Compound Potato Chips Production Line/Pringles type potato chips machine other machinery & industrial equipment

- Natural Potato Chips Production Line/potato peeling machine manufacturing machines for small business ideas other snack machines

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )  ( 0 )

( 0 )

No information

English

English

Chinese

Chinese

Select Language

Select Language