All Categories

All Categories

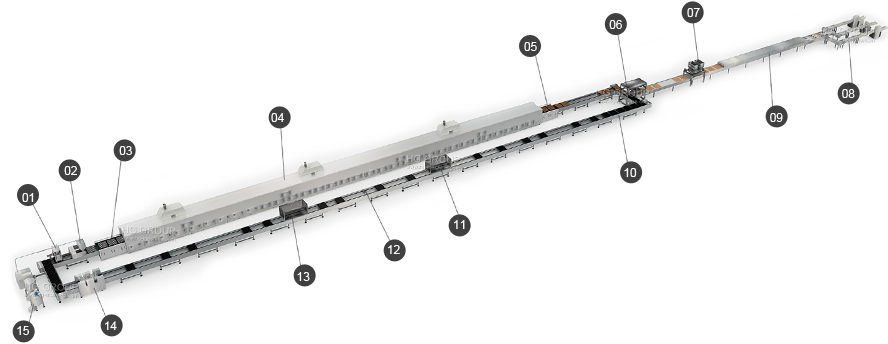

Full-automatic Center Filled Cup Cake Production Line/cup cake making machake making machine automatic cake production line

- Country of origin:

- Brand:

- HS code:

- Yield:

- Type of shipping:

- Port of shipment:

- Supply capacity:

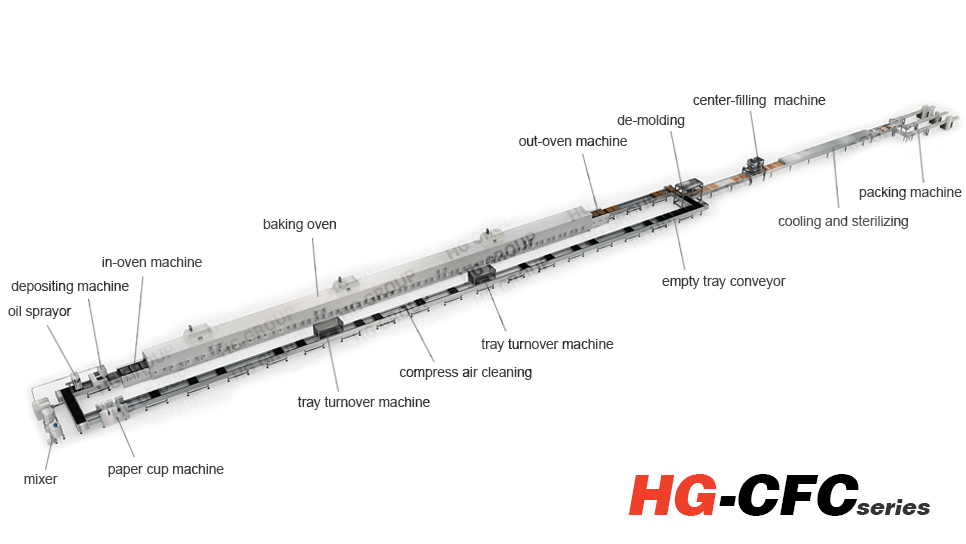

- Packing method:

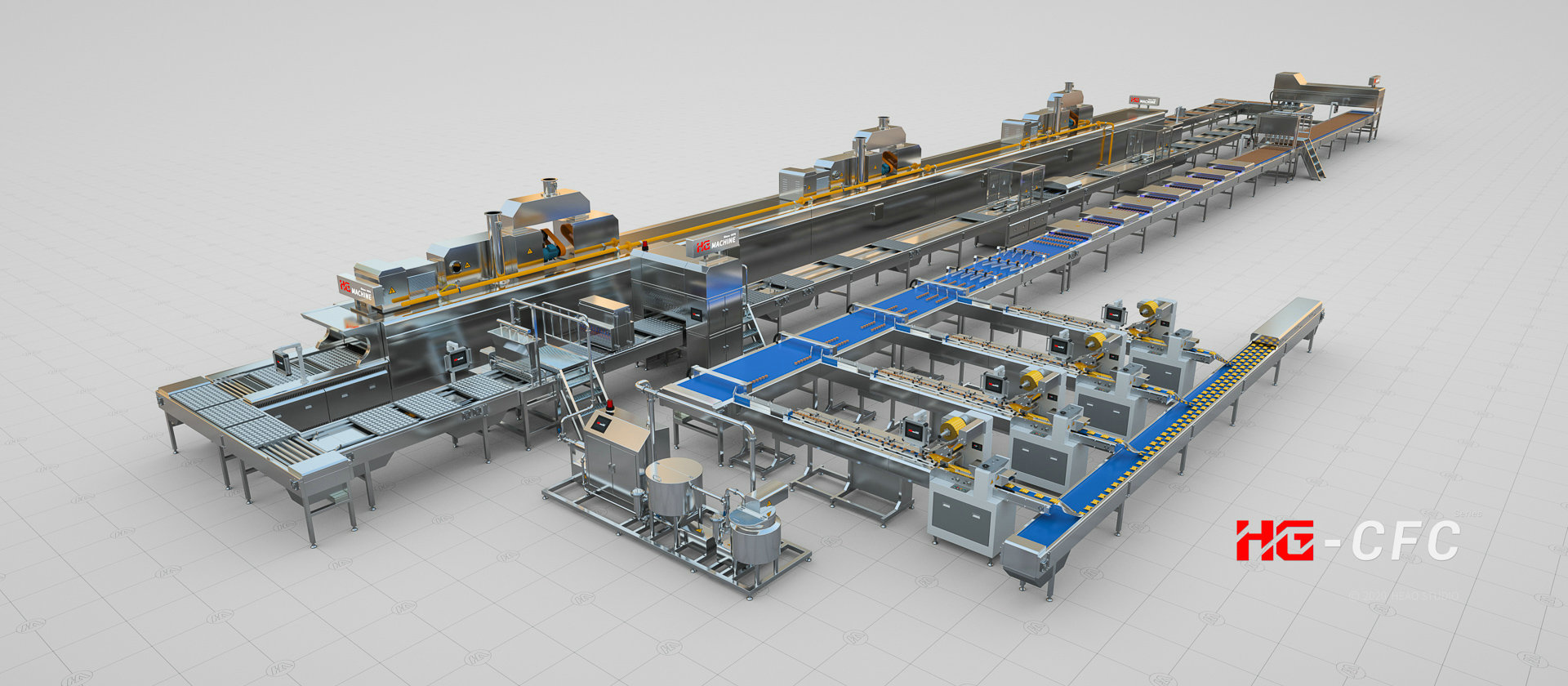

HG- CFC automatic cake production line can produce different cakes by replacing different shapes of baking molds, or can produce cupcake and filled cake by adding paper cup feeding machine and cake cream filling machine. It can produce muffin as well by mixed some chocolate in the raw material.

Capacity and Utilities :

HG Food Machinery manufacturer can provide muffin production line with different capacities in order to meet clients requirements .we have smaller capacity 250kg/h , medium size 500kg/h and bigger size 1000kg/h. In addition, we have professional engineering team to help client customize a cake production line according to client factory size.

Workshop size requirements :

U type arrangement : 60*20*3.5m

Straight arrangement : 110*6*3.5m

L arrangement : 60*30*3.5m

Power :80-120w

Gas consumption: 35-45kw

Advantages:

1)Automatic cakes production line solution from A to Z with less labor

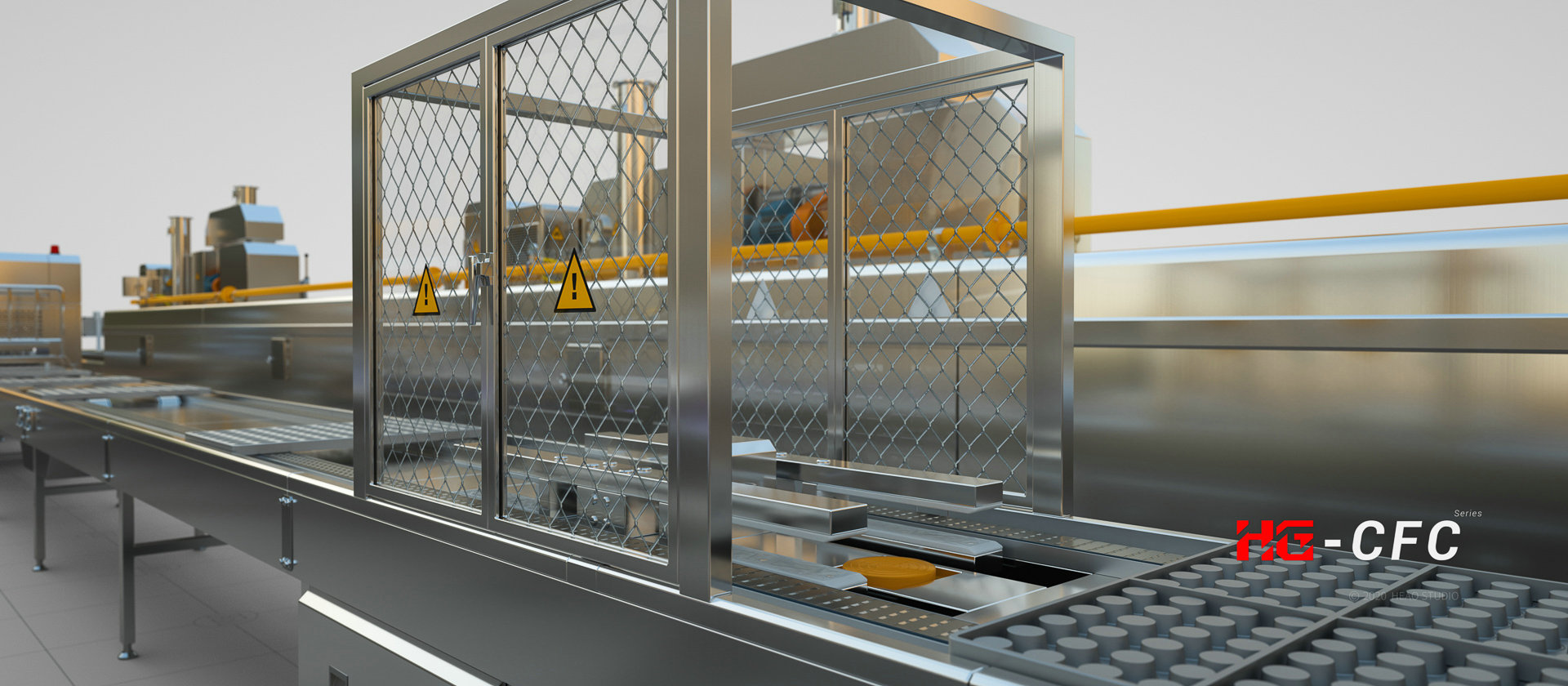

2)Touching screen PLC controlling system, easy for workers to operate

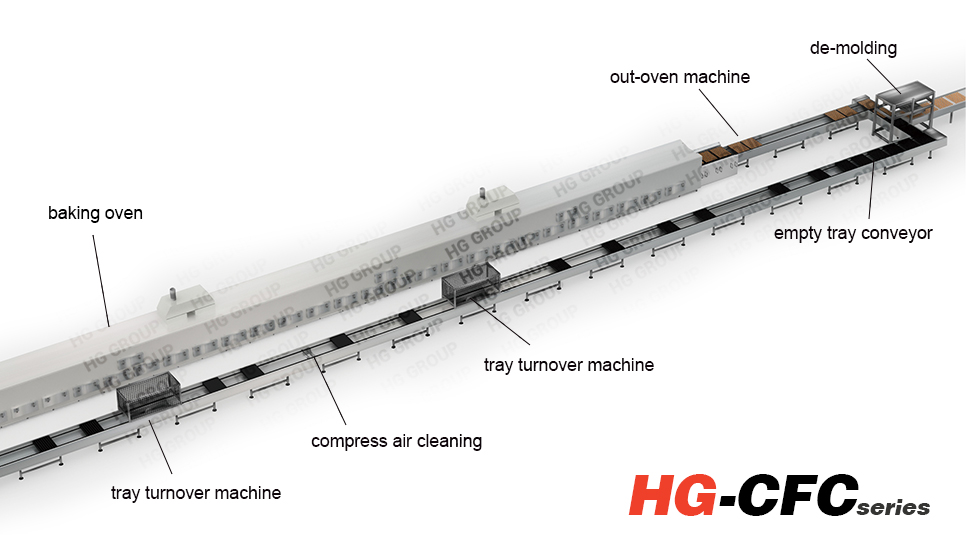

3)Hot air circulating oven with imported Japan brand burner, and separate baking zone with different temperature

4)304stainless steel raw materials with high configuration and stable performance

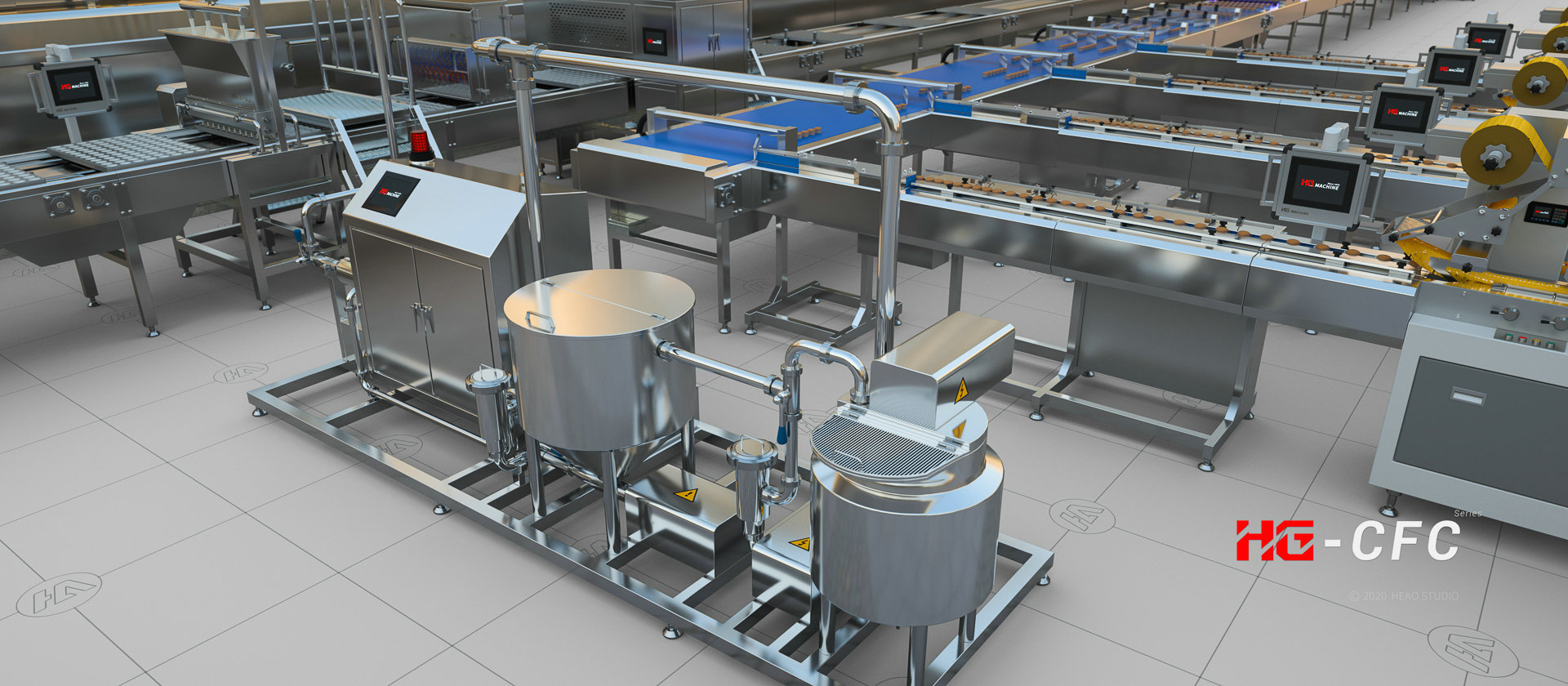

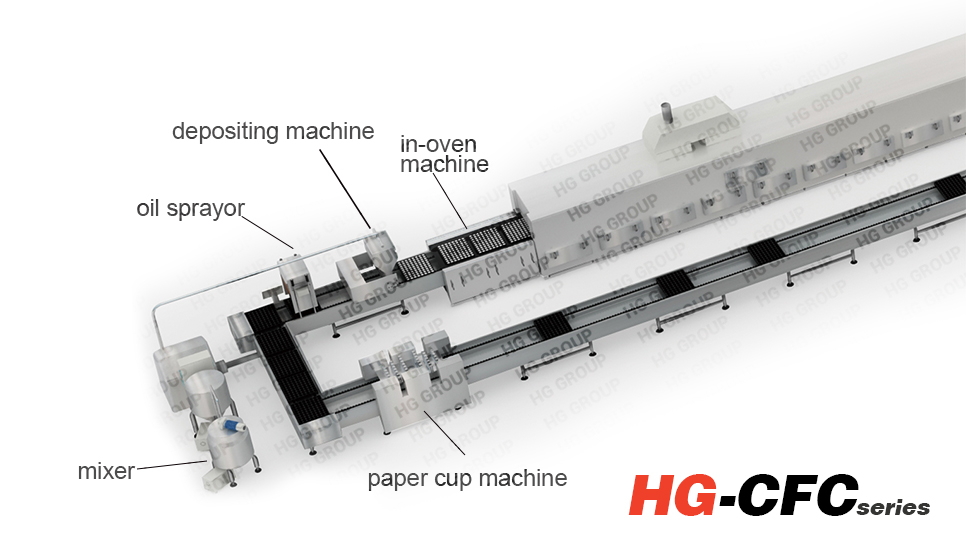

5)Aeration mixer that different with normal mixer, which can mix raw materials fine and smooth.

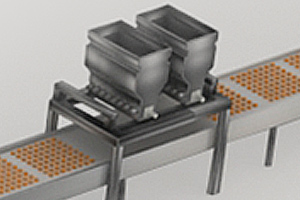

Advanced depositor that can control cake weight precisely

hg Production Line

Full-automatic Filled/Cup CakeProduce food

Apply to :::Center Cup Cake Production Line

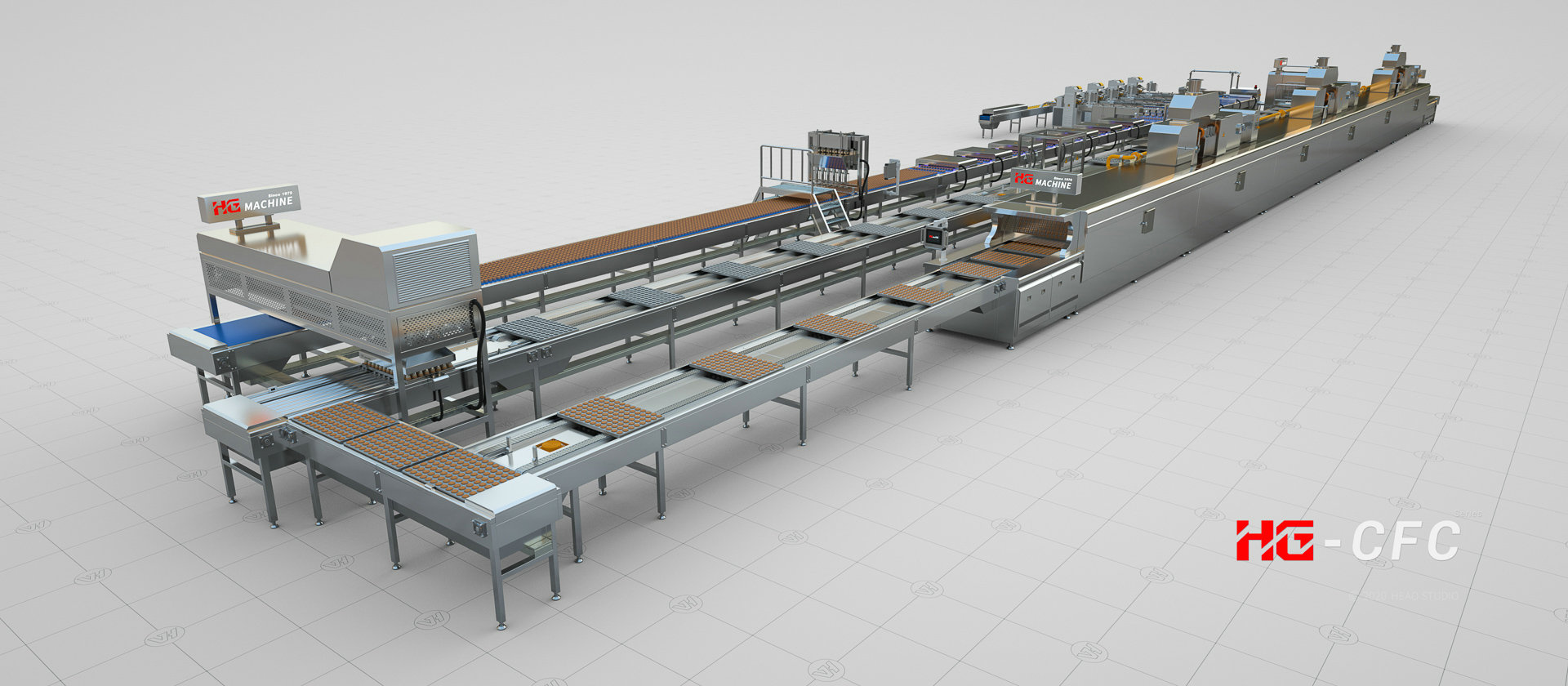

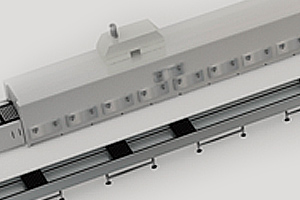

Hot-air circulation tunnel oven:As a novel baking furnace developed by our factory based on the imported equipment, it adopts the most advanced gas combustion and hot-air circulation heating mode, and has six temperature zones; after the temperature is set, the control motor is used for automatic control by a disc valve, the heat is transferred to the furnace up and down by the air duct to bake foods; the furnace has the advantages of quick heating, stable temperature, little change, automatic control of temperature, etc., therefore, the produced cakes have the advantages of good taste, softness, more uniform surface color and luster, freshness, tenderness, etc.

3394

Full-automatic Center Filled/Cup Cake Production Line is a multi-purpose fully-automatic core-filling custard pie production line which is developed based on the original equipment in order to meet various demands of different food products factories.

Center Filled / Cup Cake Machine

Cup Cake / Custard Cake /<br>Sliced Cake

Center Filled Cake

Center Filled/Cup Cake Production Line

Production Line

2oKdx9_YB_I

/hg-machine/2020/07/15/hg-cfc-3.png

/hg-machine/2020/07/15/hg-cfc-4.jpg

/hg-machine/2020/07/15/hg-cfc-5.jpg

/hg-machine/2020/07/15/hg-cfc-6.jpg

/hg-machine/2020/07/15/hg-cfc-7.jpg

/hg-machine/2020/07/15/hg-cfc-8.jpg

/hg-machine/2020/07/15/hg-cfc-9.png

/hg-machine/2020/07/15/hg-cfc-10.png

/hg-machine/2020/07/15/hg-cfc-11.png

Cup Cake / Custard Cake / Sliced Cake

Process

- 1.Mixing

- 2.Oil spraying

- 3.Forming

- 4.Rack oven baking

- 5.Out oven and cooling

- 6.De-mould

- 7.Return tray conveying

- 8.Tray turning

- 9.Compress air cleaning

- 10.Tray turning

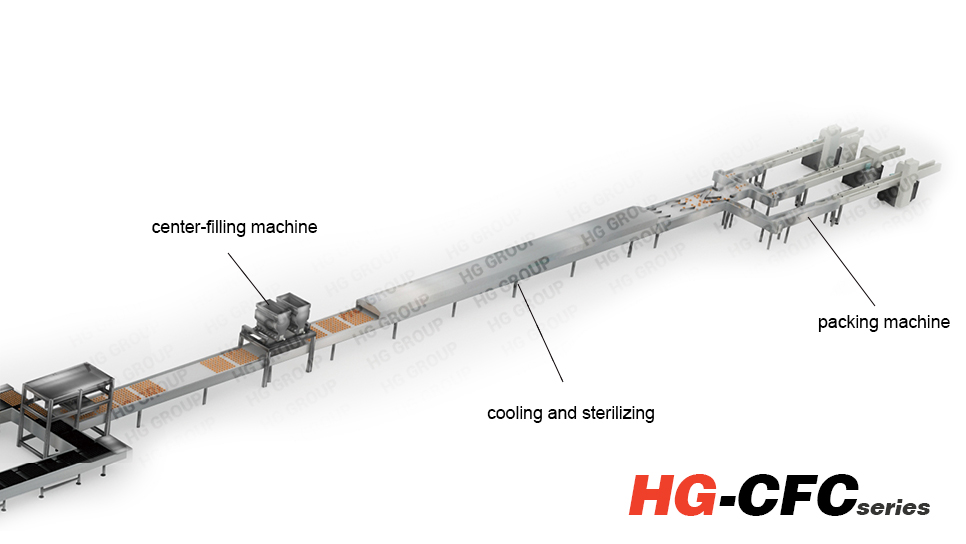

- 11.Center filling

- 12.Cooling and Sterilizing

- 13.Packaging

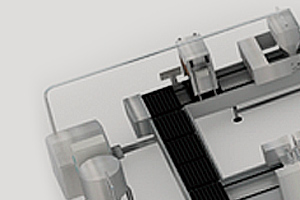

- 01oil sprayor

- 02depositing machine

- 03in-oven

machine - 04baking oven

- 05out-oven

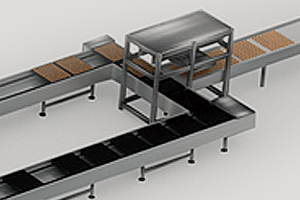

machine - 06de-molding

- 07center-filling

machine - 08packing machine

- 09cooling and

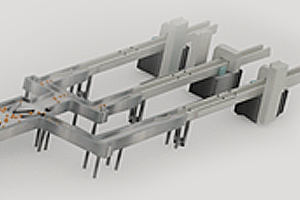

sterilizing - 10empty tray

conveyor - 11tray turnover

machine - 12compress air

cleaning - 13paper cup

machine - 14mixer

Production Process

-

mixing & oil spraying & Forming

rack oven baking

de-mould & return tray conveying

center filling

cooling and Sterilizing

packing

Types of Full-automatic Cup Cake Production Line

How to use Muffin production line

- With factory price Full automatic Baked Potato Chips Production Line/Baking potato chips machine other snack machines

- Full-automatic Bear Cake Production Line/Doughnut cake bakery equipment machine for small business bakery equipment

- Full automatic Multifunctional Wafer stick Machine/Wafer roll making production line other machinery & industrial equipment

- Full-automatic Compound Potato Chips Production Line/Pringles type potato chips machine other machinery & industrial equipment

- Natural Potato Chips Production Line/potato peeling machine manufacturing machines for small business ideas other snack machines

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )  ( 0 )

( 0 )

No information

English

English

Chinese

Chinese

Select Language

Select Language