All Categories

All Categories

Full Automatic Sandwich Cake Production Line/chocolate pie cake making machine manufacturing machines for small business ideas

- Country of origin:

- Brand:

- HS code:

- Yield:

- Type of shipping:

- Port of shipment:

- Supply capacity:

- Packing method:

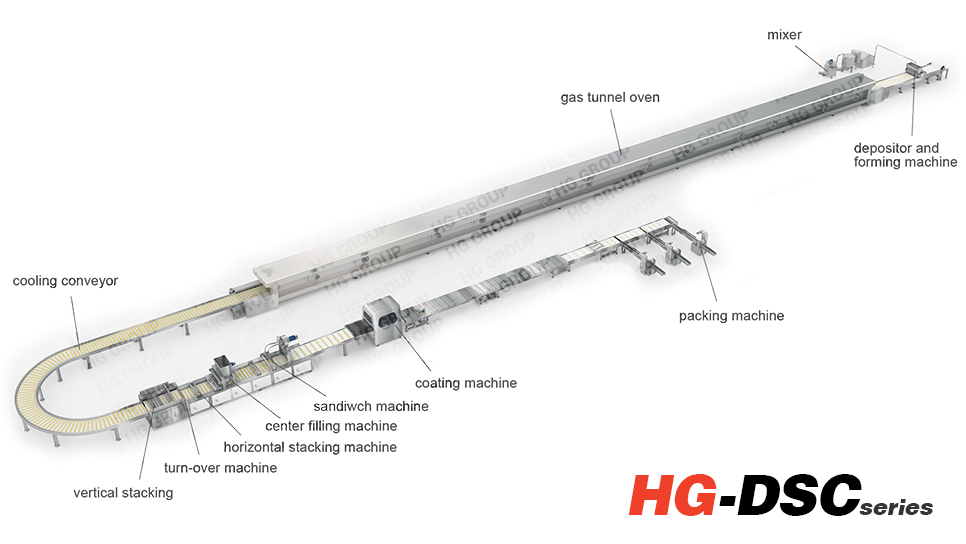

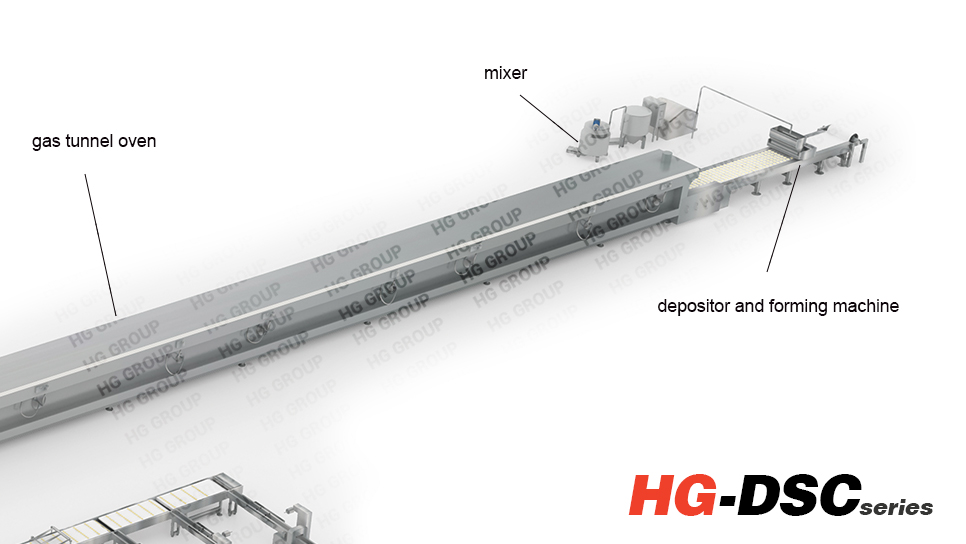

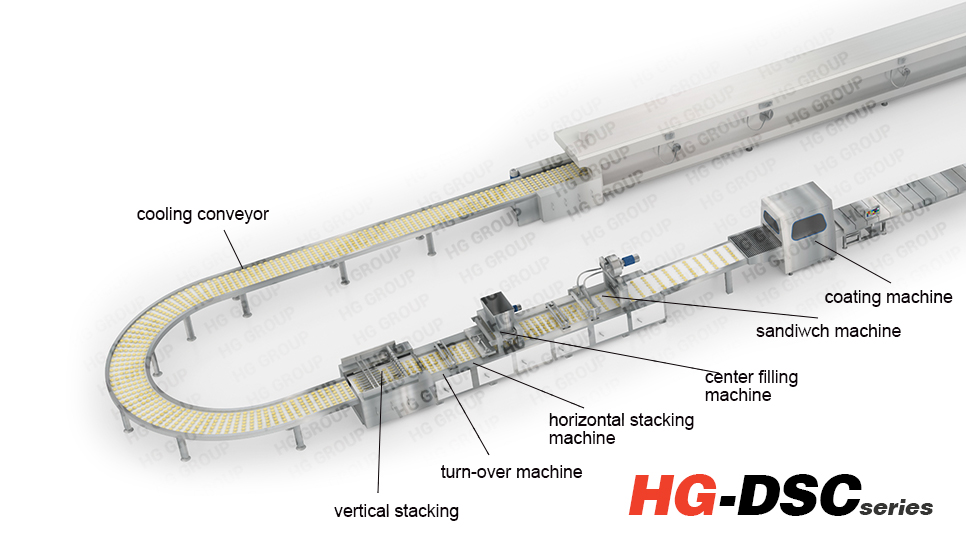

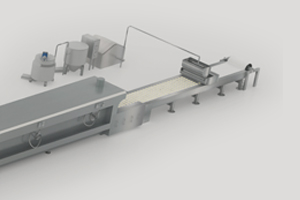

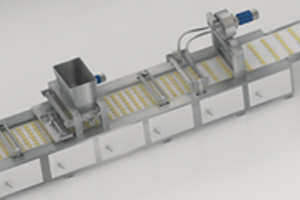

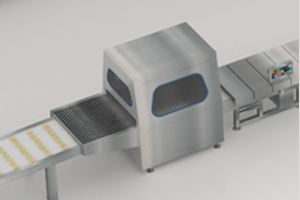

HG-DSC Full Automatic Sandwich Cake Production Line /choco pie production line is fully developed by HG GROUP, it can make sandwich cake, jaffa cake and Orion Choco pie cake. The cakes sandwiched with cream or marshmallow are deeply welcomed by consumers.The whole line include aeration mixer, paper loading machine, cake depositor, direct fire gas tunnel oven, paper recycling machine, sandwiching machine,cake sucking machine,cooling conveyor. Add the enrober line, you can also make high standard chocolate coated cake.

Capacity and Utilities :

HG Food Machinery manufacturer can provide JAFFA Cake Line with different capacities in order to meet clients requirements .we have capacity 4.5-5tons/day and 8.5-9.5topns/day (24 hours running) . We can also customize machine according to your factory size and capacity demand.

Workshop size requirements :

Length : 54meters or 80 meters

Total Power :30-40kw/h

Gas consumption: 15-20kw or 25-40kw/h

Advantages:

1)Turnkey solution from A To Z, one-stop service in HG

2)24*7 uninterrupted operation

3)Adopt the paper loading and recycling machine, keep the cake clean on the steel belt

4)304stainless steel raw materials with high configuration and stable performance

5)Aeration mixer that different with normal mixer, which can mix raw materials fine and smooth.

6)Advanced depositor that can control cake weight precisely

hg Production Line

Full-automatic Double Sandwich Cake Production LineProduce food

Apply to :::Sandwich Cake Production Line Machine

This line is mainly made up of slurry mixer, paper cup supply machine, forming machine, tunnel oven, cooling conveyor, paper recycling machine, cake arrange machine, cake turn-over machine, sandwiching machine (for cream filling), cake sucking machine. You can also add the chocolate coating machine to make high-grade products.

3397

Full Automatic Sandwich Cake Production Line uses eggs and flour as main raw materials; by mixing, feeding .baking, cooling, cake turning, sandwiching you can get the delicious chocolate sandwich pies and...

Sandwich Cake Machine

Chocolate Pie / Sandwich Cake

Sandwich Cake

Sandwich Cake Production Line

Production Line

BGogSXeOnRQ

/hg-machine/2020/07/15/hg-dsc-3.png

/hg-machine/2020/07/15/hg-dsc-4.jpg

/hg-machine/2020/07/15/hg-dsc-5.jpg

/hg-machine/2020/07/15/hg-dsc-6.jpg

/hg-machine/2020/07/15/hg-dsc-7.jpg

/hg-machine/2020/07/15/hg-dsc-8.jpg

/hg-machine/2020/07/15/hg-dsc-9.png

/hg-machine/2020/07/15/hg-dsc-10.png

/hg-machine/2020/07/15/hg-dsc-11.png

Chocolate Pie

Sandwich Cake

Process

- 1.Mixing

- 2.baking paper suppling

- 3.cake forming

- 4.baking

- 5.cooling

- 6.vertical stacking

- 7.cake turn-over

- 8.horizontal stacking

- 9.cream or mashmallow filling

- 10.sandwiching

- 11.packing

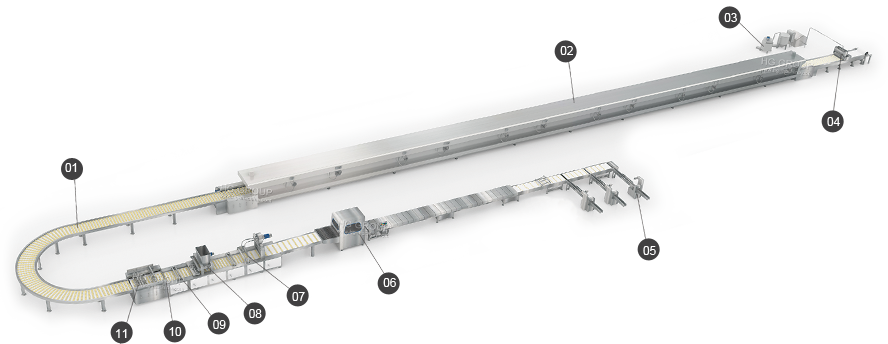

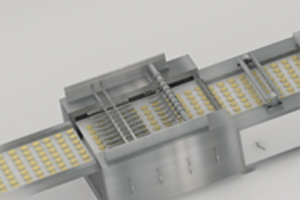

- 01cooling conveyor

- 02gas tunnel oven

- 03mixer

- 04depositor and

forming machine - 05packing machine

- 06coating machine

- 07sandiwch machine

- 08center filling

machine - 09horizontal stacking

machine - 10turn-over

machine - 11vertical stacking

Production Process

-

mixing & cake forming

baking

stacking & turn-over

cream or mashmallow filling & sandwiching

coating

packing

Daily maintenance of JAFFA Cake Line

Introduction to Full Automatic Sandwich Cake Production Line

- With factory price Full automatic Baked Potato Chips Production Line/Baking potato chips machine other snack machines

- Full-automatic Bear Cake Production Line/Doughnut cake bakery equipment machine for small business bakery equipment

- Full automatic Multifunctional Wafer stick Machine/Wafer roll making production line other machinery & industrial equipment

- Full-automatic Compound Potato Chips Production Line/Pringles type potato chips machine other machinery & industrial equipment

- Natural Potato Chips Production Line/potato peeling machine manufacturing machines for small business ideas other snack machines

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )  ( 0 )

( 0 )

No information

English

English

Chinese

Chinese

Select Language

Select Language